Product Introduction

Product Introduction

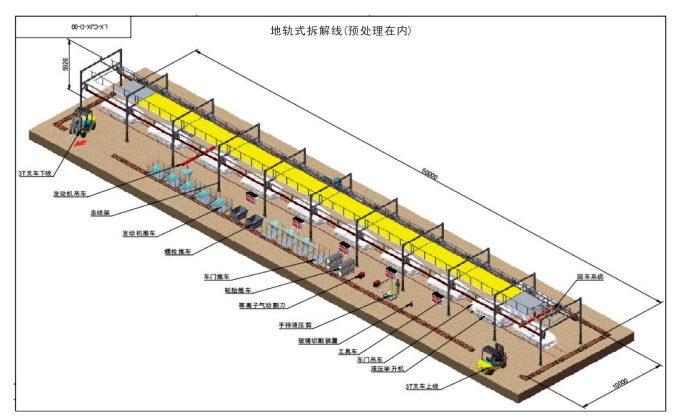

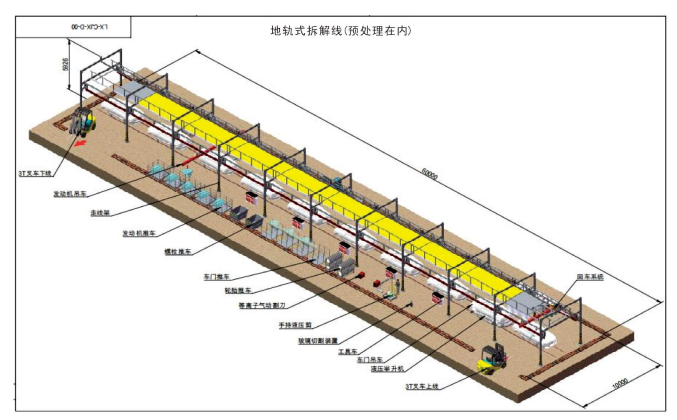

Ground rail scrap car dismantling line

Hubei Bokong specializes in the production of refined dismantling lines for scrapped vehicles. This system is independently developed by our company. According to the requirements of the national "Technical Specifications for Scrapped Vehicle Recycling and Dismantling Enterprises", the recovery rate of scrapped vehicles can be improved to the greatest extent and the value of scrapped vehicles can be maximized. The dismantling line is safe, efficient, economical and feasible, can protect the environment and save resources, and will be an inevitable trend for the industrialization of scrapped vehicle dismantling industry.

The system is a production line of refined disassembly of scrapped cars. The system adopts the ground rail transmission structure, no three wastes emissions, according to the national scrapped vehicle recycling and dismantling enterprise technical specifications, designed the scrapped vehicle dismantling assembly line with independent intellectual property rights. The system adopts ground rail transmission, the pre-disassembled old car is supported on the special car, the car is installed on the ground rail in the form of ground type, the customer is required to make the track foundation, the width of the foundation is about 13 meters, the length is about 60 meters, and the car is moved by human force.

Our company's underground rail dismantling line is a dismantling line designed to dismantle 15,000 vehicles per year. The whole dismantling line is 60 meters long, 10 meters wide and 6 meters high, and is divided into eight stations. One assembly line operation, double shift work, single-shift design dismantling capacity of 25 vehicles. 300 days, 15,000 cars a year. Each shift is staffed by 2 preprocessors and 14 assembly line disassembly stations. Personnel allocation can be reasonably adjusted according to the actual dismantling situation. When the dismantling is less than 5000 vehicles, the method of combining stations can be adopted by itself to reduce the amount of labor and meet the needs of the dismantling quantity; When the dismantling volume is less than 15,000 vehicles, the "single-shift dismantling" method can be used for dismantling, and the dismantling capacity and production efficiency will be greatly improved after the operator is skilled in dismantling.

| Working station | Length (m) | Width (m) | Height (m) | Single shift dismantling (vehicles) |

Working days (days) |

Double shift dismantling (vehicles) |

Annual disassembly capacity (vehicles) |

Single shift staffing | Foundation length (m) |

| 8 | 60 | 10 | 6 | 25 | 300 | 50 | 15000 | 16 | 60 |

Scrap car disassembly line features

1. Low-carbon green dismantling process. The waste oil is extracted into the designated container by the centralized extraction machine and can be collected centrally. After disassembling the battery, label it and store it in different categories.

2. Adopt flow disassembly operation. Realize the transfer of the car to be dismantled between various processes, saving time and reducing the labor cost of other transportation.

3. Safe and environmentally friendly, efficient disassembly. No fire, using pneumatic disassembly system and disassembly pliers to eliminate safety hazards; The cars are transported to each dismantling station through the ground rail trolley, which improves the dismantling efficiency.

4. The disassembly of the whole vehicle is processed in sections, the disassembly content of each station is relatively fixed, and the same parts are centralized into the box, which is convenient for unified collection and storage. It can reduce the skill requirements of the operator, and the operator is easy to work.

5. Can optimize the disassembly production arrangement, the use of assembly line disassembly can clearly and accurately reflect the unreasonable production of stations and the situation of not serious work, and promote the disassembly work of each station to echo and promote each other.

6. Rotation training can be carried out for operators at each station, which can improve the disassembly skills of operators in the actual disassembly production arrangement, and balance the differences caused by the difficulty and labor intensity of disassembly at stations.

| ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ |

| disassemble | disassemble | disassemble | disassemble | disassemble | disassemble | disassemble | extract |

| engine | Front and rear axle | Engine compartment accessories | seat | Steering wheel | Front and rear glass | Front and rear bumpers | Gasoline/diesel |

| gearbox | Shock absorber | ↓ | Harness of wire | airbag | four-door | Front and back covers | engine |

| ↓ | Exhaust pipe | Put into storage | Electrical appliance | Central control | Leaf plate | tyre | Oil diversion oil |

| Put into storage | Ternary catalytic converter | ↓ | ↓ | ↓ | ↓ | Brake fluid | |

| ↓ | Put into storage | Put into storage | Put into storage | Put into storage | Cooling fluid | ||

| Put into storage | Glass water | ||||||

| freon | |||||||

| battery |

Station 1: Pretreatment station: disassemble battery, pump gasoline, oil, steering oil, brake oil, coolant, glass water, recover freon, disassemble tank or storage cylinder.

Required auxiliary equipment: shear lift, comprehensive centralized extraction machine, refrigerant recovery machine, drilling extraction machine, pneumatic wrench, steel bar scissors, etc.

Use forklift to put the scrapped car on the ground rail trolley, and push it manually on the track to the pretreatment station:

First open the engine cover and support firmly; The steering oil, brake oil, coolant and glass water are extracted respectively by a comprehensive centralized pumping machine. Use refrigerant recovery machine to recover freon: after extraction, twist the cover of each liquid storage pot back to its original place; Close the engine cover gently:

Then open the front cover and trunk cover, remove the battery and gas storage tank and its pipeline: open the fuel refueling cover, and loosen the inner cover to ensure that air can enter; Press the lift button of the shear hydraulic lift machine to the position of convenient operation, and press the drop button to lock the lift machine; Unscrew the bolt on the engine oil pan and combine it; The oil tray of the central extraction machine recovers the engine oil, and screws the bolts back to the original position after recovery; Use a drilling and pumping machine to Pierce the fuel tank from the bottom of the tank and extract the fuel clean; Finally, the railway trolley carrying the car is pushed to the second station for dismantling.

Station 2: Remove tires, front and rear covers, front and rear bumpers

Required auxiliary equipment: air cannon, pneumatic wrench, pneumatic screwdriver, etc

First, push the vehicle to station two, and dismantle the tire with the wind cannon;

Then use a pneumatic wrench to remove the front and rear covers of the car, and use a pneumatic screwdriver to remove the front and rear bumpers; Finally, put the removed parts into the material box to complete the content of this station.